Foam milling excellence

FoamDesigner —

The precision tool of choice for foam design, modeling, & milling.

ZEIM means over 160 years of experience

Founded in 1860, ZEIM has become the specialist in millfoam cutting tools, providing solutions for rigid foam, soft foam, and polystyrene or medical applications.

Products range includes custom made band knife machines, reciprocating saws, and milling machines.

Milling

Cutting

Modeling

FoamDesigner

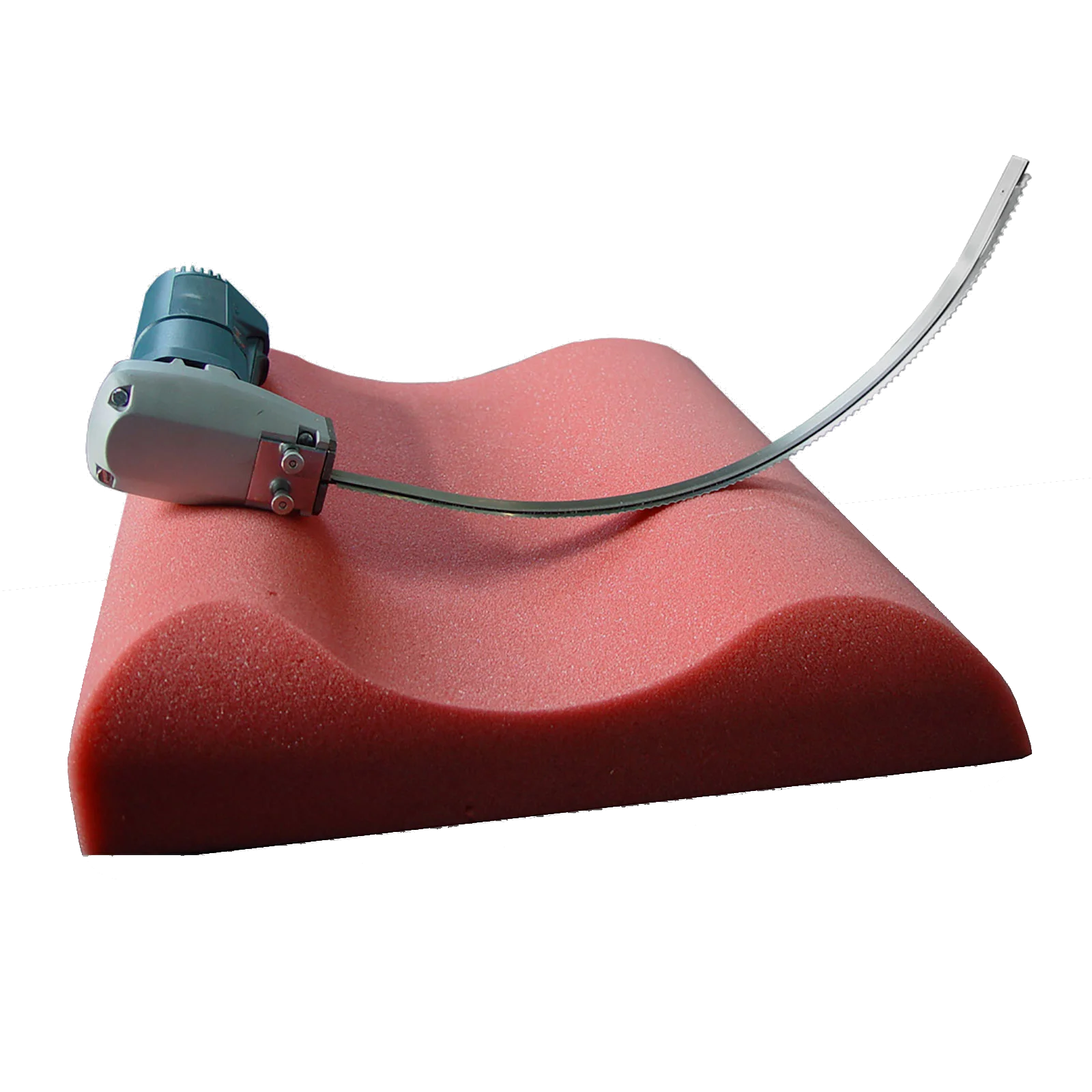

Handheld modeling

Experience precision in every curve with our handheld electric FoamDesigner modeling tool, designed especially for untethered intricate foam sculpting.

Handheld designing

Crafted for maximum comfort and control, the handheld pneumatic FoamDesigner brings your cleanest and most detailed designs to life with ease.

Foam milling with FoamDesigner

Modeling with new possibilities

The FoamDesigner, an electric or pneumatic hand tool, is indispensable in any production setting due to its wide range of interchangeable tools.

Its powerful drives and well-coordinated tool toothing ensure accuracy and smooth milling surfaces, allowing limitless customization even with soft foam materials.

Moreover, the FoamDesigner is easily connected to an industrial vacuum cleaner, promoting a clean working environment.

Submit a sketch or describe your application to receive a custom-made milling tool, with our experienced team ready to provide their expertise for optimal results.

ZEIM GMBH

Experts in Foam Milling & Polystyrene Processing

Made-to-measure tool technology

The high-quality workmanship enables a low-vibration and low-noise operation as well as fatigue-free working due to the comfortable handling.

As we look to the future, ZEIM GmbH remains steadfast in our mission to equip your business with the tools it needs to shape, cut, and finish foam products with unmatched accuracy and speed.

ZEIM is dedicated to advancing the field of foam and polystyrene processing through precision engineering and innovative technology. Above all, our expertise lies in creating specialized machinery that caters to the specific needs of industries relying on high-quality foam products, such as automotive, furniture, and medical sectors.

Innovation

We continuously develop our technology to meet the evolving demands of foam processing, ensuring our machines offer the highest level of efficiency and precision.

Quality

Each piece of equipment we manufacture undergoes rigorous testing to meet stringent quality standards, reflecting our commitment to reliability and excellence.

Service

Our relationship with clients extends beyond sales. We offer comprehensive support and maintenance services to ensure seamless machines operation in your production line.

Sustainability

We understand the importance of environmental conservation and contribute by creating energy-efficient machines which produce minimal waste.

Our Vision

Our goal is to provide products and services of outstanding quality and of the highest benefit to our customers. In pursuit of this commitment, we continually strive for innovation and excellence to exceed customer expectations and build lasting relationships.

Our Mission

We aim for satisfied customers with lasting trust in our range of services, from consultation and problem-solving to delivery, installation, and service.

Our customers’ judgment is the decisive quality benchmark for us. Get in touch with us!

Versatile Hand Milling Tool

The FoamDesigner offers unparalleled versatility with its interchangeable tools, powerful drives, and optimized tool toothing to ensure precise profiling and exceptionally smooth milling surfaces.

Personalized Solutions

We prioritize customer satisfaction and lasting trust, offering a comprehensive range of services, including consultation, problem-solving, delivery, installation, and support, to resolve your needs.

Professionals for foam milling since Generations

Zeim is a forward-thinking company rooted in tradition, specializing in foam milling and Styrofoam processing. We deliver high-quality products worldwide, from Millfoam milling tools to custom-made solutions per customer specifications – since 1860.

Have a question or need a quote?

Clean Working Environment

Connecting the FoamDesigner to an industrial vacuum cleaner helps maintain a clean workspace, preventing the accumulation of foam debris during the milling process.

Customized Milling Solutions

Tailor your FoamDesigner’s milling tool to your specific needs by providing a sketch or describing your application; our experienced team is more than happy to assist you in creating the perfect tool.

You are interested in better foam milling solutions,

designed to your specifications?

Send us an email, give us a call, or use the contact form below to send us a message.

Address

Zeim GmbH

P.O. Box 26 60

87416 Kempten/Allgäu

Germany

Phone:

+49 (0)831 – 5 20 91 45

Telefax:

+49 (0)831 – 5 20 91 47

Email: [email protected]

Looking for more answers?

What makes FoamDesigner a versatile tool for foam modeling in production settings?

The FoamDesigner is a versatile hand tool that’s essential for any production involving foam shaping. It can be operated either electrically or pneumatically and offers a wide range of interchangeable tools for different applications. Its high-revving drives and precision-cut tool teeth enable precise profiling and exceptionally smooth milling surfaces, making it suitable for even the softest foam qualities.

How does FoamDesigner contribute to a clean work environment?

Designed with workplace cleanliness in mind, the FoamDesigner can be connected to an industrial vacuum cleaner. This integration helps to remove foam particles and dust as you work, maintaining a tidy and safe environment for operators and machinery.

Can the milling tools for the FoamDesigner be customized?

Absolutely! We offer customization services for the milling tools based on your specific needs. Whether you have a detailed sketch or drawing or need guidance to describe your application, our experienced team is here to assist in designing a tool that fits your exact requirements for foam modeling tasks.

What kind of foam cutting techniques are available for furniture and automotive applications?

Zeim offers various foam cutting solutions including band knife cutting for precise cuts, profiling milling machines for creating specific foam shapes, suction-milling solutions, and hand-milling units for detailed work on foam pieces.

Can foam be modeled for medical engineering purposes?

Yes, Zeim’s portfolio includes specialized tools and milling systems for medical engineering, indicating their capability to produce precise foam shapes for medical applications.

What equipment does Zeim provide for the finishing and detailing of foam products?

Zeim supplies deflashers for removing excess material from foam products, rasp milling tools for texturing, and hot wire cutters for slicing through foam cleanly. These tools are essential for the final preparation of foam-based products.

What equipment is necessary for suction milling?

For suction milling, you require a hollow or surface cutter head, a milling motor with a hollow shaft (or a retrofit kit for existing spindles), a powerful suction unit, suction hose, and a (CNC) milling machine.

How does suction milling enhance the milling process?

Suction milling uses a powerful suction unit to remove chips of foamed plastics during the milling process, leading to higher feed rates, shorter machining times, and a clean working environment.

What advantages does suction milling offer over traditional methods?

This method improves productivity, optimizes product quality, and reduces cleaning efforts by preventing the melting of milled substances and ensuring precise, clean milling results.